Known for building the first Biological

Safety Cabinet, Baker has an array

of aseptic and containment isolators to meet

your application.

The Baker Company has been a world leader in the field of Isolation and

Containment Technology for more than 50 years.

The reputation of the Baker design and construction is based on an

ISO9001

certified quality system and years of direct experience in

Pharmaceuticals and

Life Sciences applications. With Baker's renowned

expertise in Laminar Flow HEPA

filtration, containment technology,

unequaled microbiological test facilities

and stainless steel manufacturing,

you can be sure you are working with a

full-service company able to

support any isolation project you may have.

Testing

Rigorous

Testing to

Verify Performance

While many companies claim they can build a special

containment Isolator,

it is another thing to prove it works! Because of Baker's

total dedication and

commitment to your safety, The Baker Company has

established the Isolator

Industry's most extensive testing laboratories,

equipment, and expert

personnel to assure that every unit shipped from their

facility meets or

exceeds all performance criteria.

Baker may challenge a system with Bacillus subtilis

var.Niger spores in our

unique Microbiological Testing Laboratory to assure

sterility or simulate worst

case air flow conditions in our computerized Air

Flow Management Laboratory.

Due to Bakers' stringent testing process, you are

assured of a final product

you can trust. As part of your documentation package,

you are provided with

all protocols and testing results necessary to validate

the performance of your

new equipment. Detailed IQ, OQ and PQ services can be

provided by Baker

when required for FDA approval and validation.

Advanced In-house

Testing Capabilities

- NSF-49

- ASHRAE/ANSI 110

- Mass Spectrometer Helium Leak Checking

- HEPA Filter Leak Checking

- Microbiological Aerosol Challenges

- Sterility/Decontamination Effectiveness

- Particulate Counts/Federal Standard 209E

- Passivation Assurance

- PSL Challenges

- Sound, Illumination, Vibration

- Vapor Phase Hydrogen Peroxide Cycle Times

Validated Applications:

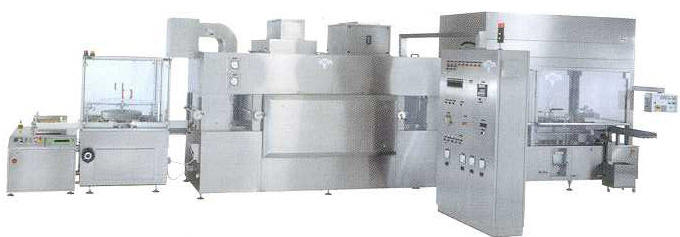

Aseptic Liquid and Powder Filling Lines Aseptic Liquid and Powder Filling Lines

Sterility Testing Sterility Testing

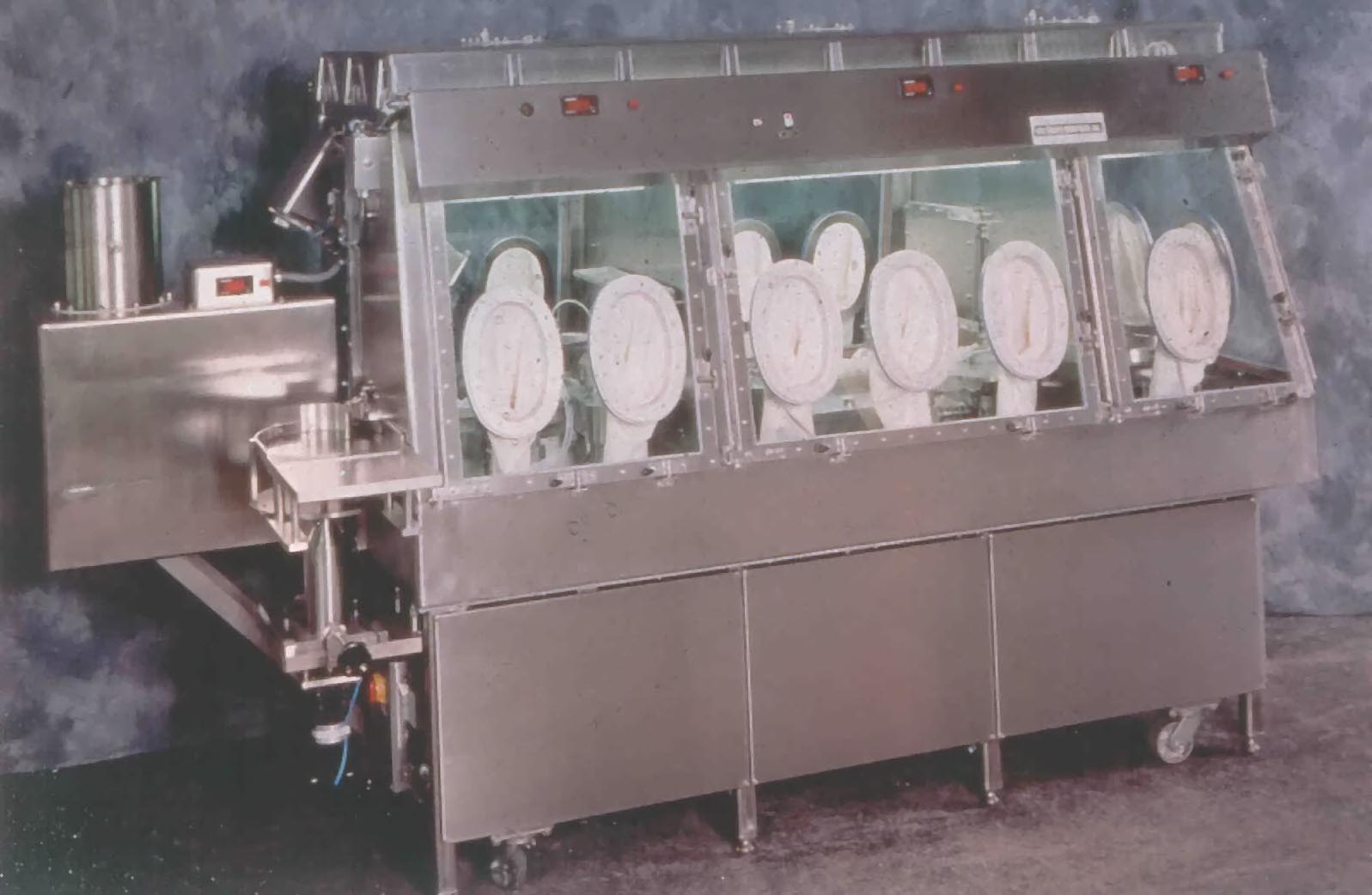

Potent Weigh & Dispense Potent Weigh & Dispense

QC Sampling QC Sampling

Radiolabel Formulation Radiolabel Formulation

Centrifuge Enclosures Centrifuge Enclosures

HEPA Filtered Downflow Booths HEPA Filtered Downflow Booths

Isolation integrated with:

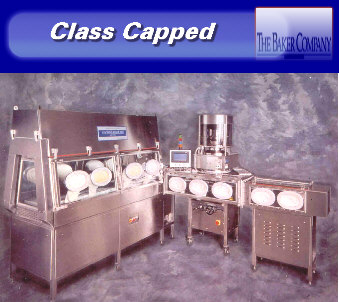

Cappers Cappers

Filter Dryers Filter Dryers

Fillers Fillers

Grinding Mills Grinding Mills

Lyophilizers Lyophilizers

Tank Charging Tank Charging

Vacuum Ovens Vacuum Ovens

ParenteralGARD®

The benefits of the ParenteralGARD® include:

-

Allows the operator to

intervene in the aseptic process without

compromising asepsis.

-

Using glove ports, operations

personnel are able to keep all barrier

panels closed and in place.

-

Sanitization with

an aerosol spray sanitant, eliminating the need for

costly VHP generators, and

airtight enclosures.

-

Used within a conventional

cleanroom - no need to construct new

facilities.

-

Personnel use familiar

gowning techniques and the ParenteralGard®

provides a secondary barrier

between the operators and the aseptic

process.

This innovative concept provides many of the benefits of a

complete Barrier

Isolation System, but without the rigorous and risky validation

requirements,

at a very attractive price. Dramatic improvements in Sterility

Assurance Levels,

up to one hundred times cleaner when compared to a

conventional class 100

cleanroom with a gowned operator are readily achieved.

Component transfer

systems (including stoppers), use the novel, patented rapid

transfer port

"Biosafe" by IDC.

These low cost and light weight ports are practical and

properly engineered to

eliminate the "ring of concern" which is common to

rotary seal

ports.

This integrated system is designed to provide significant,

reliable reduction

in both total airborne particulates and viable counts in the

critical zones of

your aseptic process. A ParenteralGARD® can be delivered to

your site in

a fraction of the time, and at a much lower cost than sealed

isolators.

Find out how you can upgrade your aseptic process in real time, for

real money.

Questions & Answers

A. ParenteralGARD® is a novel approach to

reducing the microbiological

and total particulate levels and improving quality

assurance in ANY process

run under aseptic conditions. Working within a

conventional cleanroom, the

ParenteralGARD® could be the effective, and

practical answer to the ongoing

efforts many companies are struggling with

today: To buy an isolator,

or not to buy....

A. ParenteralGARD® takes advantage of a

simple fact that the "dirtiest"

element within any aseptic process is

the human operator. The same basic

technology has been used for over 25 years to

try and provide some sort of

boundary between the humans and the product being

processed. Unfortunately,

conventional curtains and panels must still be moved

out of the way to allow

the operations personnel access to the equipment when

adjustments are

required. The ParenteralGARD® solves that problem by allowing

the operators

to have access to the equipment WITHOUT opening the

ParenteralGARD®

panels. Therefore, the aseptic process is protected from

exposure to human

and equipment borne particulate load, whether viable or not.

A. While the concept of sealed isolators,

running in unclassified areas in a

pharmaceutical plant, has been actively

explored since 1992, the number of

successful installations of such technology

is still quite low. Someday, the cost

effectiveness and practicality of aseptic

processes running inside sealed isolators

in low cost plant space may be proven.

If you need to have a process running

NOW, and at a REASONABLE COST, take a

close look at the ParenteralGARD®.

A. The cost of investing in, or upgrading a

conventional Class 1000 (Grade B)

cleanroom and installation of a ParenteralGARD

A. An isolator is not a sterilizing device!

At best, it can only reduce the

likelihood of adventitious contaminants entering

into an aseptic process.

Isolator operation requires the same care and even more

operator training,

compared to conventional aseptic processes, to run

successfully. The elegant

simplicity of the ParenteralGARD® allows you to take

advantage of your current

infrastructure and experienced personnel to IMPROVE

the sterility assurance

level of your aseptic processes.

A. The development of the ParenteralGARD®

has been underway for many years.

The apparent simplicity is deceptive;

extensive engineering studies and testing

were required to create the versatile,

successful ParenteralGard® system.

There is far more to a ParenteralGARD® than

gloveports and plastic panels.

Let BAKER and VICTOR INTERNATIONAL show

you how the ParenteralGARD® can improve your process

at an affordable

price, in the same millennium

that you started the project!

|