|

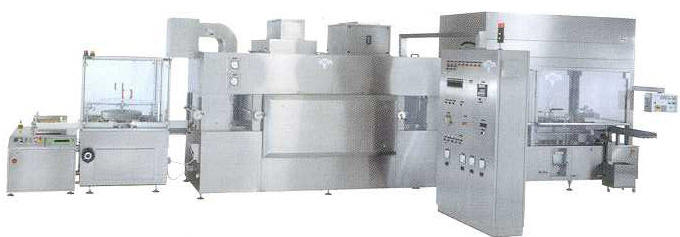

MAP Systems®

provides patented, state-of-the-art gas flushing equipment for atmosphere

critical parenteral applications.

MAP Systems has

provided atmosphere critical packaging solutions for over 20 years.

MAP Systems will guarantee low residual oxygen levels, down to parts per

million, and/or precise gas

mixtures in every parenteral container or package in order to optimize your

product and its shelf life.

With the MAP Systems patented technology and extensive engineering capabilities,

MAP Systems is your

partner in atmosphere critical packaging solutions.

MAP Systems works with your package and your packaging machinery, at line speed,

to deliver

guaranteed results.

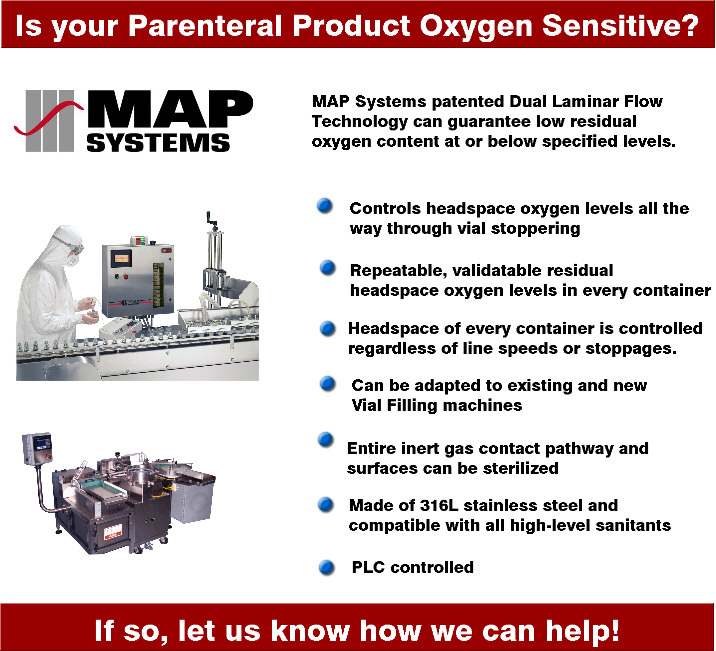

MAP Systems® patented Dual Laminar Flow

Technology can guarantee

residual oxygen levels at or below 1%, down to parts per million, at the time of

sealing.

MAP Systems® technology guarantees complete control of headspace all the way

through stoppering.

System can be added to new and existing filling machines.

Benefits

-

Precision control of residual Oxygen/Atmosphere

-

Elimination of seal contamination caused by turbulence

-

Product quality and stability characteristics are maintained

-

Dramatic increase in-line speed for existing MAP applications

Features

-

PLC Logic control sequencing for hands-off operation

-

Optional multiple point Oxygen analysis system with PID feedback

-

Precision control of container Oxygen/Atmosphere levels

-

Automatic speed compensating throttling control

-

Touch screen operator interface with system diagnostic display

-

Recipe recall storage setting system

-

Validation support

|